Pipeline Inspection

Rainwater harvesting is an eco-friendly and sustainable approach to conserve water for future use. However, to ensure the quality of the harvested rainwater, it is important to conduct regular inspections of the entire system, including the pipeline. Pipeline inspection in rainwater harvesting involves checking the condition of the pipes that carry rainwater from the catchment area to the storage tank. Rainwater harvesting systems are designed to collect rainwater from rooftops and other catchment areas, which is then channelled through a series of pipes and filters before being stored in a tank. However, over time, the pipes may develop leaks, cracks, or other damages that can compromise the quality of the water collected. Regular inspections of the pipes can help detect such issues early, before they lead to significant damage or contamination of the stored water.

Pipeline Inspection

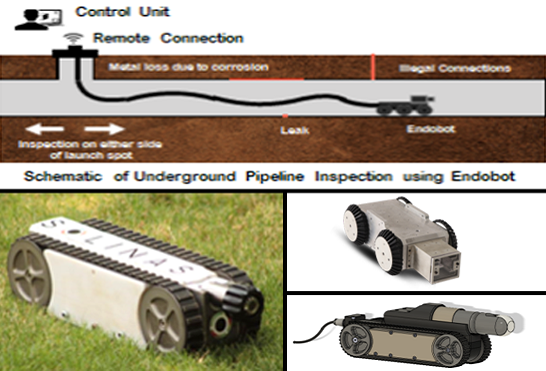

There are different methods of inspecting pipelines in rainwater harvesting systems, depending on the size and complexity of the system. One common method is visual inspection, where a trained technician inspects the pipes visually, looking for signs of damage, corrosion, or blockage. This method is typically used for small-scale rainwater harvesting systems that have simple pipelines. For larger and more complex systems, however, more advanced methods of pipeline inspection may be needed. One such method is the use of CCTV cameras, which are inserted into the pipes to capture high-resolution images of the inside of the pipes.

-

01Penetration & Leakage

✓ Multiple ferrules identified across one length

✓ Leading to water accumulation & contamination

✓ Defect location identified in 1 Dig, at 39 mts from the site of inspection

✓ Rectification & solution in a Day

-

02Benefits

✓ Cost savings by 10X in digging and labour (as no empirical data of ferrules available)

✓ Time saving of 3-5 Days

✓ Assessment of further ferrules condition along the length of the pipeline